Guidance Memo | GM-2025-04

Guidance for Completing Final Plans of Record (FPOR) for Lower-Potency Hemp Edible Manufacturer Applicants

10/15/2025 11:32:39 AM

Background

As the Office of Cannabis Management (OCM) has begun reviewing submitted final plans of record (FPORs) from applicants for lower-potency hemp edible manufacturer licenses, OCM has observed several common issues and questions related to certain sections. To assist applicants and support timely processing, OCM is issuing this additional guidance to clarify expectations and help you prepare an approvable FPOR.

Definitions

Co-manufacturing: The practice of outsourcing product production to a third-party manufacturer who makes goods on behalf of a brand.

Co-packing: When a company outsources the packaging of its products to a specialized third-party provider known as a co-packer.

Guidance for preparing a complete final plan of record (FPOR)

- Only submit information for the manufacturing or processes that your facility intends to perform. If you will only perform one part of the manufacturing process like bottling or canning, then answer the FPOR prompts with only those parts in mind.

- If you are co-manufacturing for another company, you must submit the information about the products and manufacturing procedures you are using in your facility, not the business that you are packing for.

- If you are co-packing for another company, you must submit information about the packing procedure that you are performing. You do not need to submit recipes or processing procedures related to those products.

- If you own a product brand but do not physically perform any of the manufacturing, packing, or labeling, then you do not need to submit the recipes or processing procedures related to those products.

- Note that many manufacturing practices mean you may be receiving input products that require a license if in-state, or OCM approval if out-of-state, to produce. It is your responsibility as a license holder to ensure all inputs are compliant with Minnesota regulations.

- Clarification on site diagram:

- The diagram does not need to be created using design software. It can be created in any format—it can be simply drawn by hand and scanned with a smartphone—that works best for the business to demonstrate that the site meets requirements.

- LPHE manufacturer businesses must comply with state and local building, fire, and zoning codes, requirements, and regulations. Further, all hemp manufacturing must take place in a facility using equipment that meets the applicable health and safety requirements established by the office, including requirements for cleaning and testing machinery between production of different products. Review Minnesota Statutes, section 342.45, subdivisions 2, 6. To demonstrate compliance with these requirements, applicants for an LPHE manufacturer license must submit a site diagram of the physical layout of the facility that includes requirements requested in the online fillable form.

- For items marked “if applicable” in the instructions for the diagram, applicants should add the items to the diagram only if the business already has them in place. However, items marked “if applicable” are not required information and will not impact licensing review if they are not included.

- The Site Security and Operations Plan asks applicants to “Identify and describe all products the business intends to manufacture. Fill out a separate entry for each product. Products with multiple flavors may be listed on the same entry, but you must list each flavoring ingredient separately.”

- All LPHE products that a business manufactures at the time of application must be listed. Products that have multiple flavors or variations may be included on the same entry.

- This information is essential for OCM to prepare for your pre-license inspection.

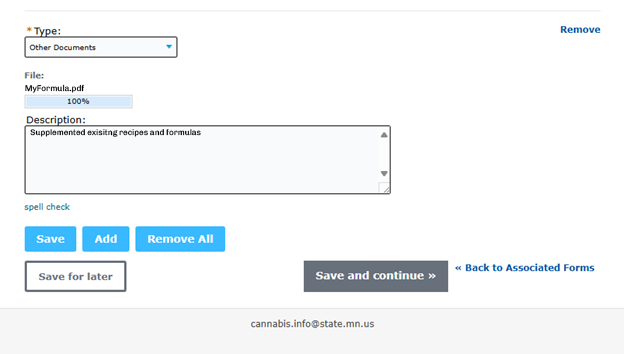

- Instead of completing the product description on the FPOR template for each product, you may submit your existing recipes or formulations if it includes all the information we request. You should write “see supplement” in the Product Description section on the FPOR and then upload the documents in Accela when you upload the FPOR.

- In the future, the business must submit new FPORs at the time of renewal and before any material changes are implemented. For the purpose of this prompt, a material change would include the addition of any new product categories pursuant to Minnesota Administrative Rules, part 9810.2100, subpart 2. For example, if a beverage manufacturer added a new type of beverage during the license term, they do not need to submit an updated FPOR. However, a beverage manufacturer that intends to begin manufacturing edibles would need to submit an updated FPOR.

- Reference standard operating procedures (SOPs) clearly and accurately. If you refer to SOPs in your FPOR, you must ensure they are up to date, reflect your current operational practices, and are available for review by OCM inspectors during the on-site inspection. You may do this in one of two ways:

- Include the full text or relevant sections of the SOP directly in the FPOR.

- Provide a summary of the SOPs contents, along with the SOP’s title, version number, and approved date.*

- Know your opportunities to revise and resubmit. If your FPORs do not meet OCM’s compliance standards, OCM will provide you with specific feedback outlining the areas that require clarification or correction. Please note that deficiencies requiring revision will delay the issuance of your license or result in a denied license.

*Note: Listing an SOP title alone is insufficient. Your FPOR must contain enough detail for OCM to confirm the SOP exists and supports the practices you describe.